I get down to the -8 range on my chamber without much issue, it does take a couple days to do it, which for a chamber the size of mine is not too surprising. And the whole thing is nitrile or viton seals. Of course I do have a 2000l/s turbo on it...Dennis P Brown wrote:Most people heat the outside of the chamber; using radiant energy would be very inefficient. One can get heating tape at some hardware stores (for outside pipes.) A variac could control the temperature.

For a fusor, as I understand from posts here, 10^-6 torr is fine relative to removing unwanted trace gasses. If the chamber can bottom that out range, then it is doing very well.

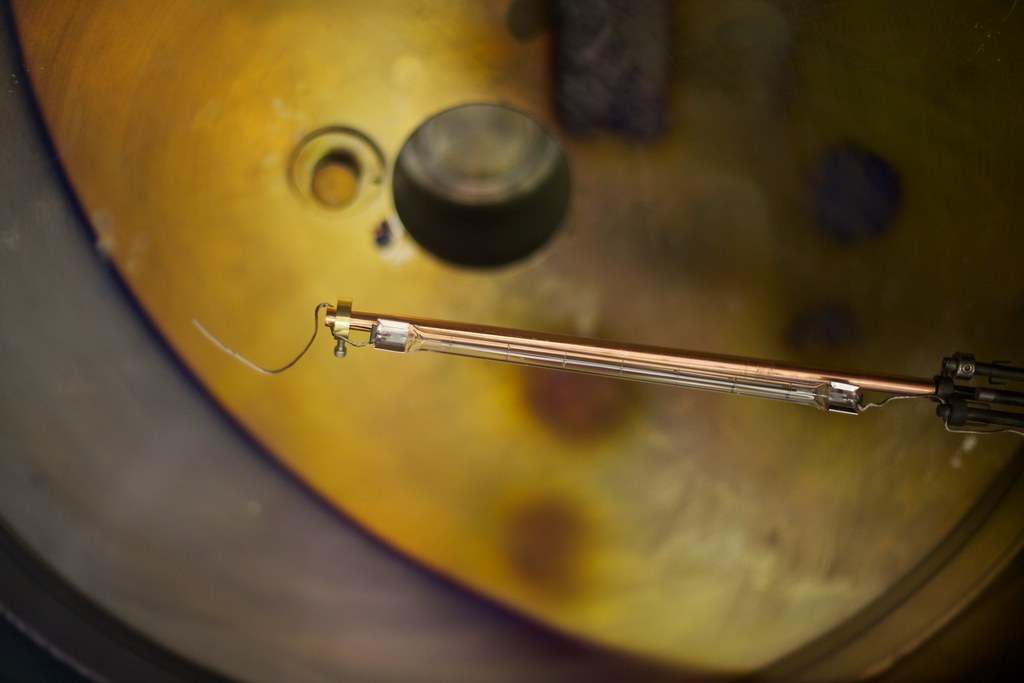

You can heat the outside. What I do is use a 1kw linear quartz halogen lamp to heat things up from the inside. This way you get heating on any surface within line of sight of the lamp. You can also use shortwave mercury UV lamps instead. The UV knocks the water molecules off the wall.

IMG_8204 by macona, on Flickr

IMG_8204 by macona, on Flickr IMG_8209 by macona, on Flickr

IMG_8209 by macona, on Flickr